Clean Energy

Expertise

Projects

Invenergy Services

Partners

Who We Are

News & Insights

by Invenergy Team

“Innovate in Everything” is something of a motto at Invenergy Services, and it extends to how we take care of our blades. As a wind O&M service provider for well over a decade, Invenergy Services has extensive knowledge & experience regarding blade maintenance and repair.

- Minor cracks and damages can intensify quickly if left unaddressed.

- Blade erosion can easily go undetected if not regularly inspected and can be costly to repair.

- Investments in proper blade maintenance and repair leads to increased availability and production as well as decreased, long term maintenance costs.

“

“Improved data collection and analysis has allowed Invenergy Services to develop a greater understanding of repair expectations & associated costs to better plan for the future.”Katelyn Reynolds, Senior Mechanical Engineer, Operations Engineering”

Tracking Results & Continual Improvement

In the Summer of 2017, the first trial of the campaign model was deployed at a handful of Texas sites and proved successful. In 2018, the blade campaign was expanded to the entire Invenergy fleet, with over 400 repairs completed. Following the 2018 campaign, careful analysis of the existing processes and pain points brought upon new ideas for further improvement. In particular, Invenergy Services developed more sophisticated repair tracking tools to increase communication and collaboration with vendors. Refinements in vendor selection and scheduling also increased campaign efficiency. In 2019, the average repair cost decreased by 24% and the average time for major repair decreased by 37%, with over 360 repairs completed. Today, even more refinements are in progress. Invenergy Services is applying lessons learned and capitalizing on deeper knowledge of vendor capabilities, which has led to substantial improvements each year.

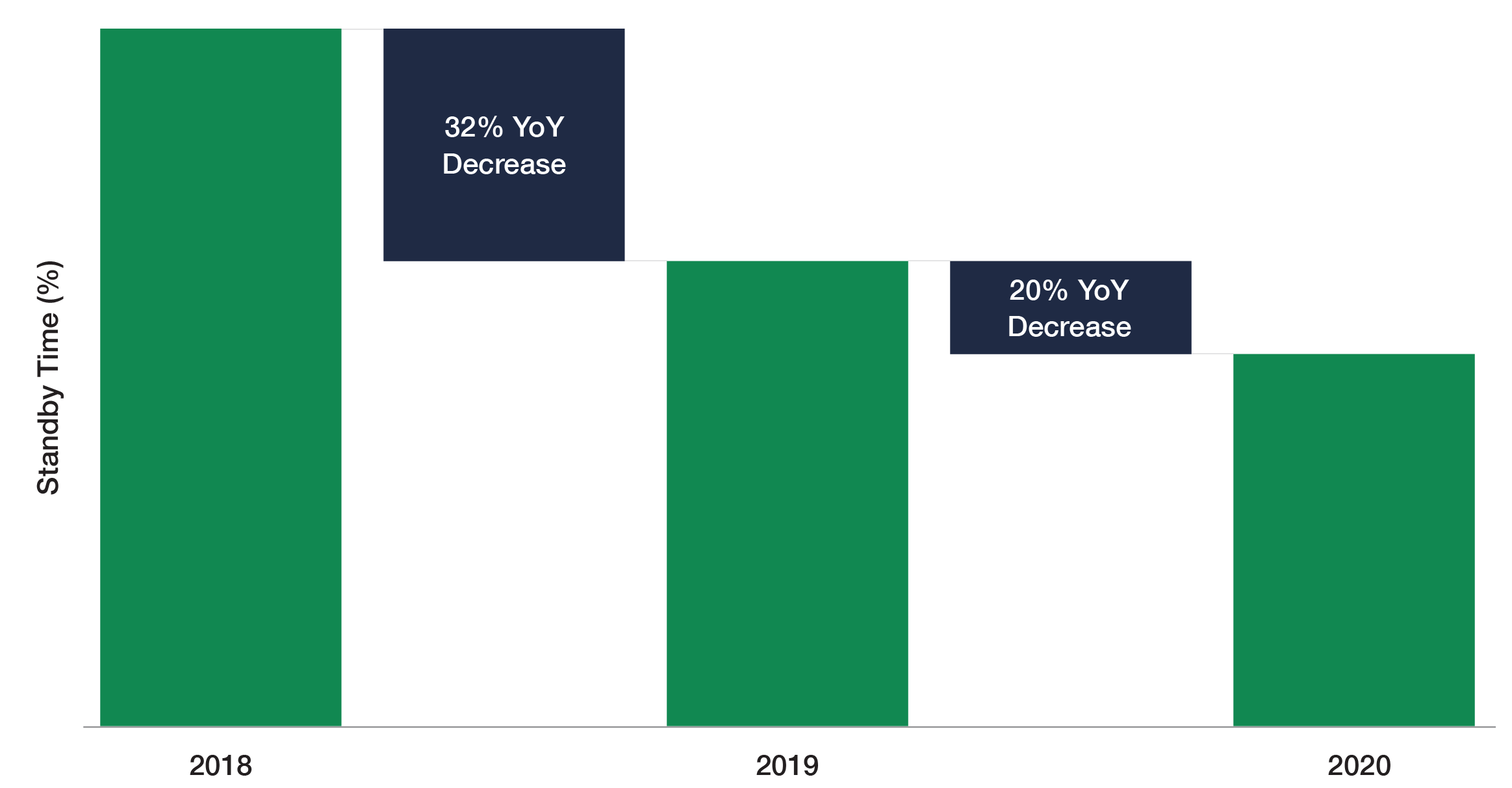

Decreasing Percentage of Standby Time per Repair Year Over Year

Latest Campaign Improvements

The 2020 campaign brought about even more improvement opportunities, specifically with vendor accountability. A new workflow mandates that vendor technicians submit daily timesheets that are recorded, tracked, and sent directly to Invenergy Services site managers for verification. By increasing accountability through automation, campaign managers now have a system that calculates the cost of repair while ensuring labor hours are not overcharged. The real-time cost tracking enables the team to make quick and informed decisions based on up-to-date information. Further increasing efficiencies, the mechanical engineering team has designed a comprehensive damage severity matrix used for repair prioritization. This matrix guides decision-making when unexpected events occur, such as weather-related damages or cancellations. With the pandemic affecting day-to-day operations, this matrix streamlined the ability to adapt and make the necessary changes to keep the campaign safely moving ahead. Following the phased COVID-19 response protocols put in place (

Phase I

&

Phase II

), the 2020 campaign commenced under key safety considerations and adjustments.

Interested in learning more about the Invenergy Services Blade Campaign?

Contact Brad Purtell, Director, Invenergy Services Business Development at

bpurtell@invenergy.com

to learn more.

Download a

Follow

Expertise

Projects

Invenergy Services

News & Insights

© 2023 Invenergy