Clean Energy

Expertise

Projects

Invenergy Services

Partners

Who We Are

News & Insights

by Invenergy Team

From a single computer to a world-class operations hub

The Invenergy Control Center has been improving its Markets and Operations functions over the last 13 years.

Invenergy’s primary goal in the operation of renewable generation facilities is to maximize the value of assets by creating optimized, efficient solutions. Invenergy’s Control Center has been improving its Markets and Operations functions over the last 13 years. From a small conference room in rural Texas, to a state-of-the-art Control Room in downtown Chicago, Standardization, Automation, and Optimization have been key areas of focus in the Invenergy Control Center. These areas have enabled significant growth without a commensurate increase in staffing levels and overhead costs.

Renewable services have become extremely cost-competitive, and therefore, it is important for operators to find ways to reduce costs while maintaining a high level of availability and performance. Automation can help reduce labor costs by creating more efficient task completion.

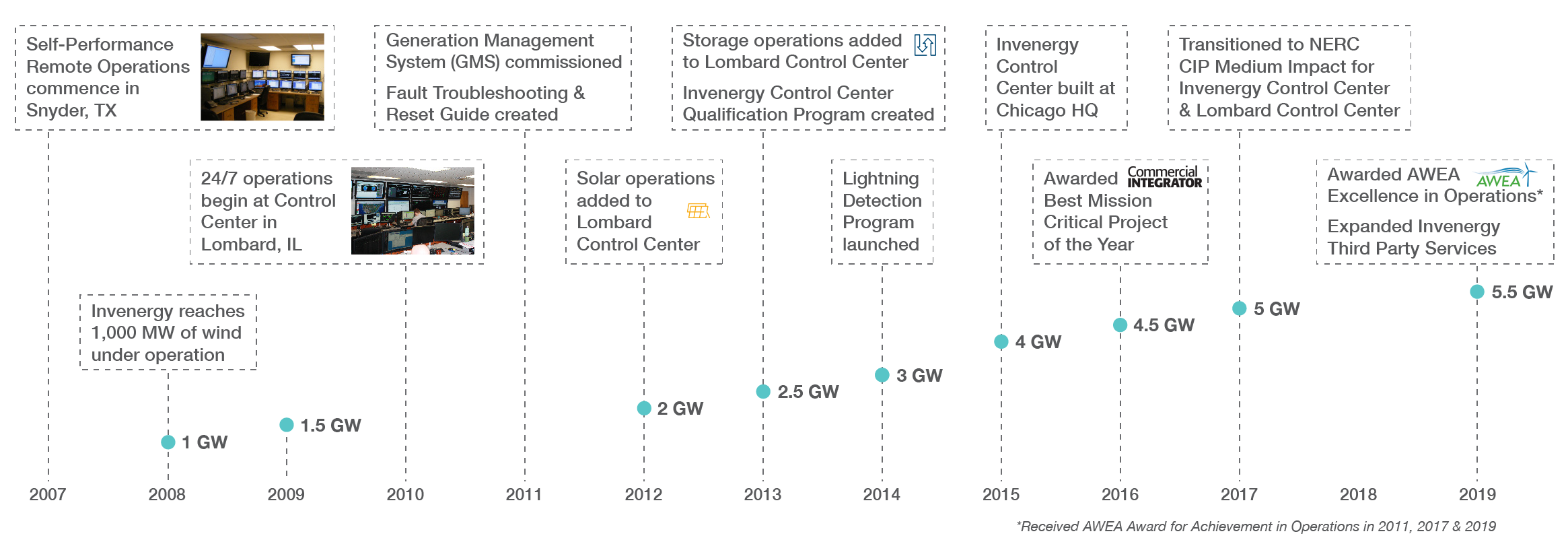

Invenergy began self-operation in 2007, removing the OEM from maintenance activities and remote operations. Starting with a single off-duty technician resetting turbines after hours, Invenergy soon realized that a 24/7 solution was needed for both operations and market participation as the portfolio grew to over 1.5 gigawatts within 3 years. In 2010, Invenergy opened the Invenergy Control Center in Lombard, Illinois. This allowed for even more standardization, automation and optimization.

Invenergy Control Center Timeline

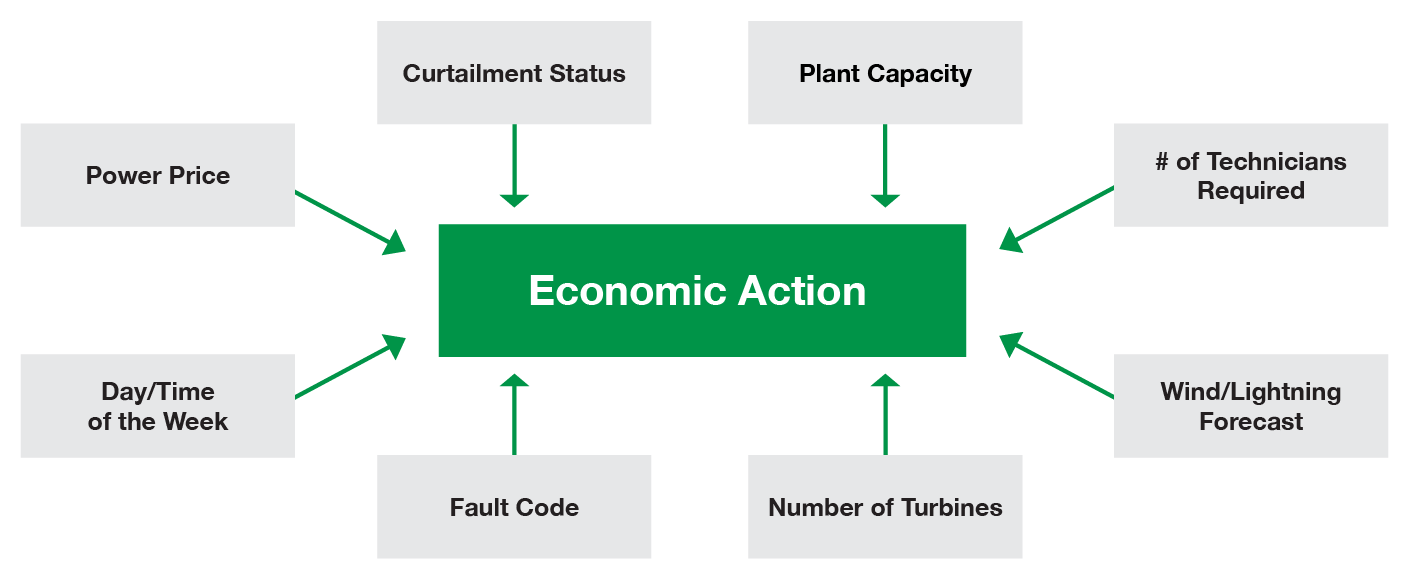

Standardization When operating 50+ facilities, standardization is key. This was highly evident in 2011 when Invenergy was operating approximately 15 facilities. Each site had unique criteria for their call-out policy for down turbines. Standardization optimized availability and overtime costs associated with these callout protocols. Rising to the challenge, the Power Markets team developed a “Cost Analysis Program,” which provides a cost benefit analysis to the Operators and Site Managers to help decide when to dispatch techs after hours. The new Program helped the Invenergy Control Center standardize its process for down turbines while realizing costs savings by making more economically beneficial decisions. A financial review conducted after the first 18 months of the program showed that procedural gains, those which were saved or gained by adhering to the Cost Analysis result, were over $1.3 million.

Cost Analysis Program

AutomationWith several hundred megawatts of wind in the ERCOT RTO in early 2010, and the frequency of economic curtailments rising, the Invenergy Control Center Operators spent a large portion of their time following a Security-Constrained Economic Dispatch (SCED). SCED changes were occurring every five minutes and had to follow a 10 megawatts/minute ramp rate over five projects. In 2011, Invenergy completed commissioning of a centralized SCADA system (Generation Management System “GMS”) to perform dispatch automatically. This relieved 2-3 hours per 12-hour shift for Operators to perform other functions, equating to 1,460–2,190 workhours (close to one full-time employee) every year.

OptimizationAfter 4 ½ years of operating in the original control center in Lombard, IL, Invenergy had grown to 3.5 gigawatts of wind capacity and brought solar and storage technologies into the Invenergy Control Center. Invenergy made the investment to build a new state-of-the-art Control Center in the Chicago headquarters. The operators continuously updated screen design and alarm logic throughout the years, including custom alarms for events not identifiable using simple SCADA systems. These adjustments enabled Invenergy to identify anomalies impacting production or equipment quickly and reliably and respond with corrective actions. Examples include flagging derate events that are not caught by a faulting condition or missed availability numbers; or flagging certain Park Management conditions to meet NERC Compliance.

Final TakeawaysContinuous growth, year over year, has made Invenergy a leader amongst renewable generation operators throughout the country. As of 2019, Invenergy operates close to 5.5 gigawatts of renewable generation from its Control Center with a pipeline of several gigawatts over the next few years. As Invenergy’s operating portfolio grows with Invenergy-owned and third party-owned assets, so too will the Invenergy Control Center and its capabilities.

Interested in optimizing asset performance? Invenergy Services can help.Contact Brad Purtell, Director, Invenergy Services Business Development at bpurtell@invenergy.com to learn more.

Download a

Follow

Expertise

Projects

Invenergy Services

Partners

News & Insights

© 2023 Invenergy